EXHAUST GAS CLEANING (SCRUBBERS)

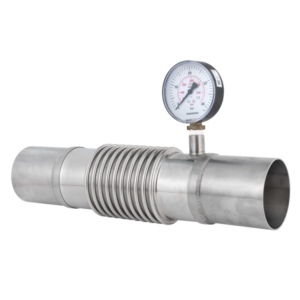

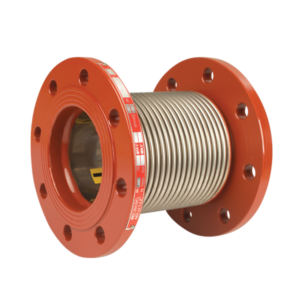

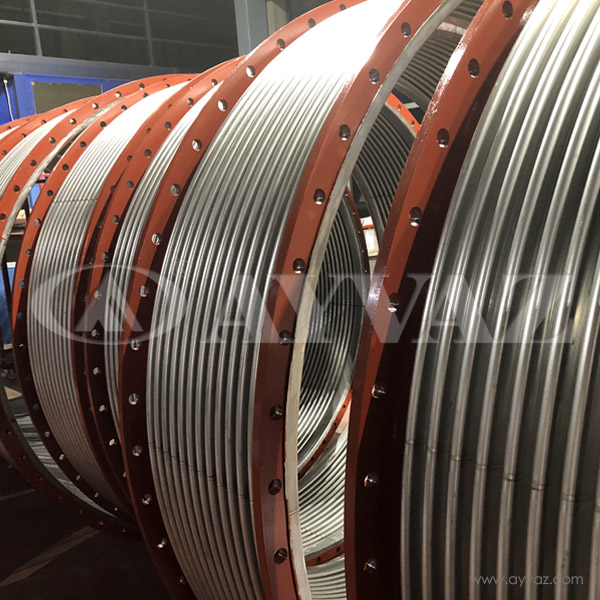

Exhaust gas cleaning systems are also known as scrubbers are used for exhaust gas cleaning in order to meet the emission limits of allowable emission.The design of the expansion joint is specified by the amount of axial movements in the system.

In most cases, expansion joints for exhaust gas cleaning (scrubber) used are single bellow or double bellow expansion joints with flanges. Scrubbers may get damaged from vibrations and movements in the systems, sufficient protection for scrubbers and connected equipment can be provided by installation of expansion joints.

Application Areas

• Cruise liners

• Container ships

• Ferries

• Cargo ships

• Freighters

• Passenger ships

• Oil tankers etc.

Diameter, installation length and design criteria of expansion joints for exhaust gas cleaning (scrubber) can be changed upon the scrubber system's design and vessel type. Ayvaz is able to design and produce single or double bellows expansion joints up to DN6000 for both new built vessels and retrofit projects. Bellows design and expansion joint constructions are done in complience with EJMA 10, EN 14917, EN 13480, EN13445-3, ASME B31.3

BELLOWS DESIGN

Bellows of expansion joints are designed according to EJMA 10 code. For high pressure applications multi layered bellows with reinforcing rings. According to the requested features like type of transported media, spring rate values (axial, lateral, angular) or operation temperature, pressure & life cycle bellows material could be customized.

Material:

Inlet: The exhaust gas that is fed into the scrubber is dry and heated and therefore austenitic steels are sufficient. Inlet joints are typically made from 1.4541 or 1.4404

Outlet: when the media exits the scrubber it has cooled down and may contain acidic properties, especially for the cases that sea water is used for cooling. For these reasons the expansion joints for exhaust gas cleaning (scrubber) are made from 254 SMO, Duplex or super Duplex

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: DN 15-6000

• Design pressure: Up to 150 bar (de¬pending on the diameter and tem¬perature)

• Lifting capacity: Up to 16 ton

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.