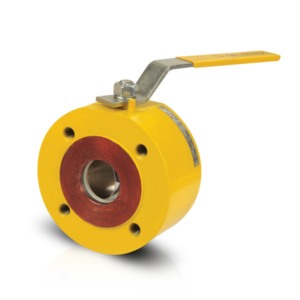

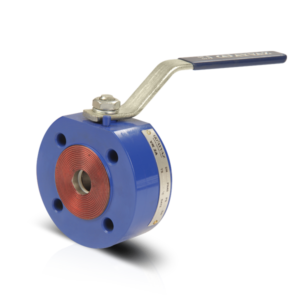

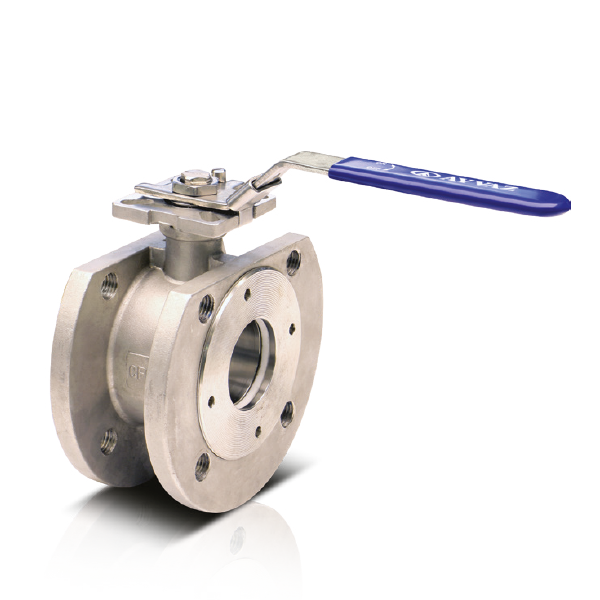

MV-14 Monoblock Valve

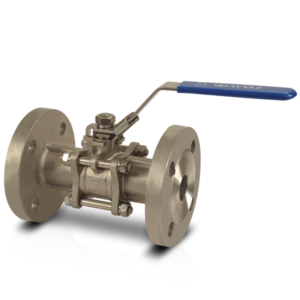

Sealing surface damage may occur in the following reasons: - Scratching of sphere and / or surface due to solid particles trapped between sphere and seat rings during closing - Corrosion of seat rings - Deformation of seat rings due to overheating.

Apply force to the arrow indicated on the lever when opening and closing the valve. Do not continue to apply force when the arm is turned against the stop pin. If the valve does not open and close with an appropriate closing torque, do not force the valve using levers or similar tools to increase the closing torque. Because this can increase irreparable damage to valve parts.

Attention:

Avoid physical application to the valve's sphere without take precaution for closing.

Avoid sudden rapid opening in order to prevent the occurrence of water hammers in the ball valves.

Notice:

If the valve is to be in the closed position for a long time in the installation, open and close the valve once a week to prevent the formation of lime and sediment layer.

Advantages

- Lightweight

- Monoblock Design

- Short Spacing

- Space-Saving

- Easy Installation

- Universal Application

Documents

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.