Boiler Proportional Feed Water System

It is not possible to read a certain water level in the boiler during steam production by the classical water level indicator. When the steam is produced, the water level is composed of bubbles of steam-water mixture and the water level cannot be detected due to the fact that the water level is in motion. The water level outside the boiler is lower than the actual water level in the boiler. The water level outside the boiler is lower than the actual water level in the boiler. The reason for this is that, the water density is higher at outside level indicator.Factors affecting the difference between the actual water level and the water level read from the outside indicator:

1-Boiler steam capacity

2-Height of boiler level indicator according to the boiler

3-Chemical properties of boiler water

4-Length of the sensor casing below the water level.

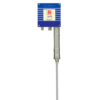

The operation of the feed pump and the control of low and high water levels are only possible with the level control sensors immersed in the boiler.The advantages of systems are:

1-Measuring sensors measure the actual level due to their presence in the boiler.

2-Self-test level sensors eliminate the need to test the system every day.

3-The systems of these sensors are safe because they are composed of moving elements and no maintenance is required.

Documents

AYVAZ STEAM AND CONDENSATE LEVEL CONTROL

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.