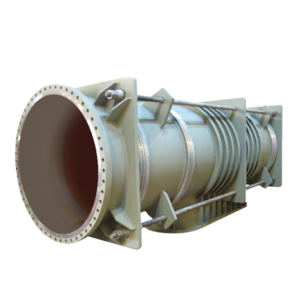

CROSSOVER EXPANSION JOINTS (STEAM TURBINES)

Steam Turbines in coal-fired plants, and in combined cycle plants, use crossover piping to transfer high-pressure, high temperature steam from the IP Turbine to LP Turbine(s). Expansion joints are located within most crossover systems to absorb the thermal growth of the piping.

Although pressure balanced crossover expansion joints are the most common type of expansion joint used throughout the industry, the design of pressure balanced expansion joints vary greatly between various turbines and turbine manufacturers.

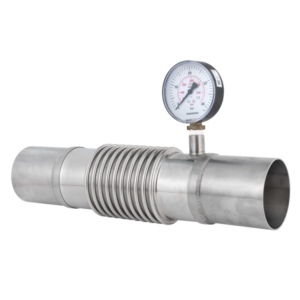

BELLOWS DESIGN

Bellows of crossover expansion joints are designed according to EJMA 10 code. For high pressure applications multi layered bellows with reinforcing rings. According to the requested features like type of transported media, spring rate values (axial, lateral, angular) or operation temperature, pressure & life cycle bellows material could be customized.

CONSTRUCTION

Expansion Joints are the parts of pip¬ing system of pressurized equip¬ment. In this respect construction of the expansion joints are designed and produced according to European pressurized equipment directive (PED 2014/68/EU) as well as American Nation¬al Standard for piping process ASME Section VIII Div 1&2, ASME B 31.3.

All components of the expansion joints like, pipes, caps, flanges, tie rods etc… are checked by piping stress ana¬lysis thus enable us to se¬lect material type & thickness accord¬ing to permissible stress values.

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: DN 15-6000

• Design pressure: Up to 150 bar (de¬pending on the diameter and tem¬perature)

• Lifting capacity: Up to 16 ton

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.