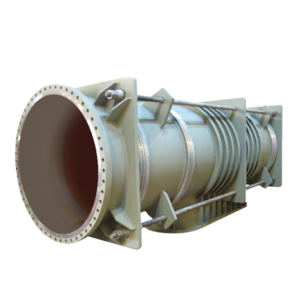

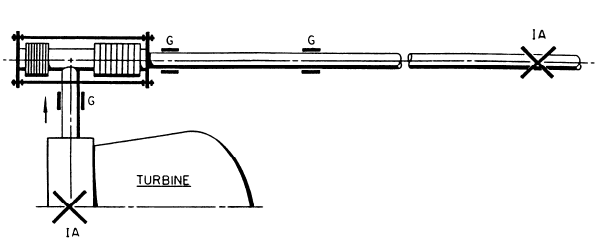

ELBOW TYPE PRESSURE BALANCED EXPANSION JOINT

An elbow type pressure balanced Expansion Joint is used most frequently in applications similar to those shown for the single Expansion Joint, but where pressure loading upon piping or equipment is considered excessive or objectionable.The major advantage of the pressure balanced design is its ability to absorb externally imposed axial movement without imposing pressure loading on the system.

The force resulting from the bellows spring rate is not eliminated. In fact, it is usually increased over that of a single Expansion Joint, since both the flow bellows and the balancing bellows must be compressed or elongated and the combined axial force acts upon the piping or equipment. Since the forces to move the bellows are generally of a low order of magnitude, these are usually not objectionable, except in cases involving extremely light equipment with close clearance moving parts which might be affected by small forces.

Above figure shows a typical application of a pressure balanced Expansion Joint for combined axial movement and lateral deflection. Both the anchor at the end of the piping run and that on the turbine are intermediate anchors and only directional guiding is required. By proper design, the guide directly above the turbine can be made to absorb the axial movement forces of the Expansion Joint without imposing these on the turbine. The only force imposed on the turbine is that which is required to deflect the Expansion Joint laterally.

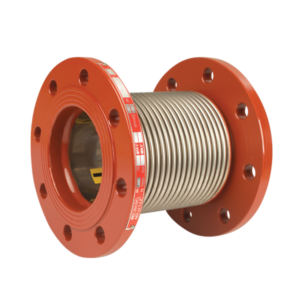

BELLOWS DESIGN

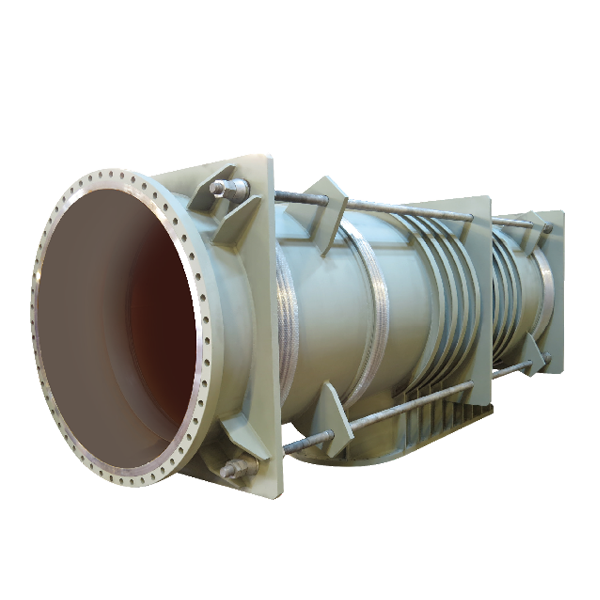

Bellows of pressure balanced expansion joints are designed according to EJMA 10 code. For high pressure applications multi layered bellows with reinforcing rings. According to the requested features like type of transported media, spring rate values (axial, lateral, angular) or operation temperature, pressure & life cycle bellows material could be customized.

CONSTRUCTION

Expansion Joints are the parts of piping system of pressurized equipment. In this respect construction of the expansion joints are designed and produced according to European pressurized equipment directive (PED 2014/68/EU) as well as American National Standard for piping process ASME Section VIII Div 1&2, ASME B 31.3.

All components of the expansion joints like, pipes, caps, flanges, tie rods etc… are checked by piping stress analysis thus enable us to select material type & thickness according to permissible stress values.

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: DN 15-6000

• Design pressure: Up to 150 bar (depending on the diameter and temperature)

• Lifting capacity: Up to 16 ton

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.

AYVAZ SPECIAL EXPANSION JOINTS

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.