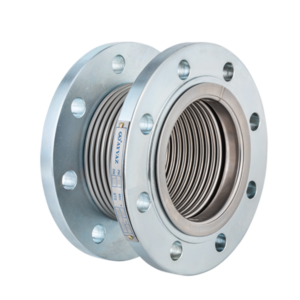

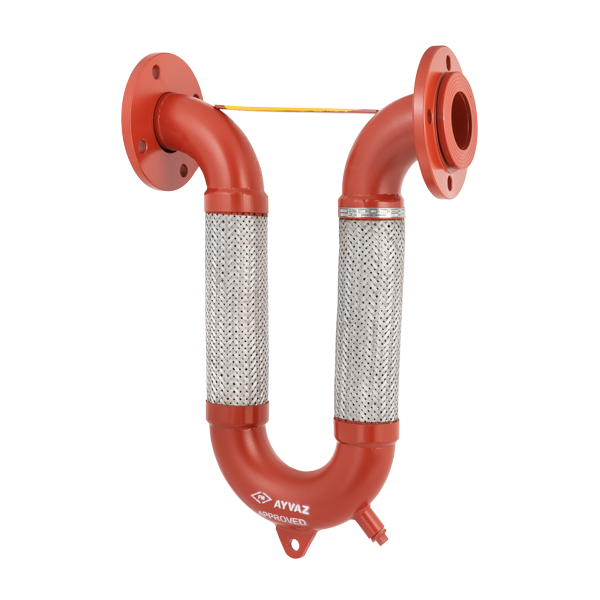

Loop Joint

The loop joint is designed to move in any direction making it a simple, all-in-one joint for a variety of applications. There’s no limit to the seismic applications that loop joints can handle. It can even be designed with lined hose for high velocity, double-braid for high pressures, and all stainless steel construction for media compatibility.

Piping used in applications and locations subject to seismic conditions have their own set of unexpected random movements and greater costs to overcome. The random motion common to earthquakes requires that seismic expansion joints be capable of movement in any direction. Of the 6 possible directions. Ayvaz Loop joint’s orientation can be changed relative to the piping, further minimizing the likelihood of compressive movement.

Bellow Material

Stainless Steel AISI 304 (opt.321,316L,316TI,309)

Braiding Material

Stainless Steel AISI 304

Connection Types

Floating Flanged, Welded Ended, Grooved & Threaded

Flange Material

PN 16, St.37.2 as standard, the material can be customised on request

Operating Temperature

-10°C/+550°C

Operating Pressure

175 psi & 250 psi

TYPES

U-FLEX

Rotating Flanges

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

Welded End

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

Grooved End

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

Threaded EN-10226-1(R)

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

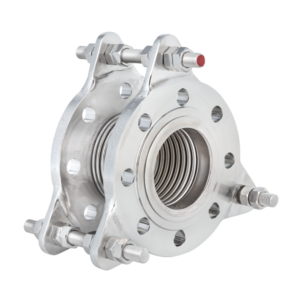

V-FLEX

Rotating Flanges

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

Welded End

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

Grooved End

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

Threaded EN-10226-1(R)

40 mm movement

100 mm movement

200 mm movement

400 mm movement

600 mm movement

INQUIRY FORM

Please send us your request using our contact form; We will contact you immediately.