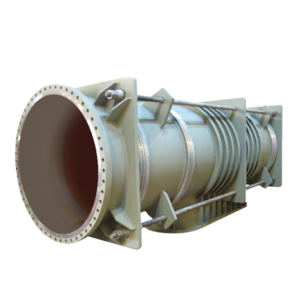

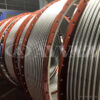

RECTANGULAR EXPANSION JOINTS

Rectangular expansion joints have a variety of application areas such as power generation, thermal power plants, petrochemical, refining, chemical, and steel industries usually for hot air and dust ducts.

As there are no standard duct sizes, and due to the wide range of pressure and temperature combinations, each rectangular expansion joint is custom designed and produced in order to provide the most economical solution that will absorb the thermal movements of the system in which it is installed.

DESIGN

Like circular pipe expansion joints, rectangular expansion joints absorb all three types of movement: axial, lateral and angular. For the purpose of designing rectangular bellows, it is critical to know in which direction the lateral and angular movements will occur, i.e. parallel to the long and/or short side of the bellows. Unlike circular bellows where the pressure stress is a circumferential membrane (hoop) stress, the rectangular bellows must be designed for longitudinal (beam) bending stresses. Long unsupported lengths must frequently be supported to prevent excessive deflection and stresses of the bellows element.

In certain applications, covers and liners can perform the function of pressure supports. Typical convolution geometry's and corner construction details are shown below. The "V" convolution profile will be supplied with single miter corners, unless otherwise specified. Round corner bellows will always be constructed using the "U" convolution profile.

CONSTRUCTION

Expansion Joints are the parts of pip¬ing system of pressurized equip¬ment. In this respect construction of the expansion joints are designed and produced according to European pressurized equipment directive (PED 2014/68/EU) as well as American Nation¬al Standard for piping process ASME Section VIII Div 1&2, ASME B 31.3.

All components of the expansion joints like, pipes, caps, flanges, tie rods etc… are checked by piping stress ana¬lysis thus enable us to se¬lect material type & thickness accord¬ing to permissible stress values.

GENERAL CAPABILITY RANGE FOR AYVAZ EXPANSION JOINTS

• Dimension: 6000x6000mm

• Design pressure: Up to 150 bar (de¬pending on the diameter and tem¬perature)

• Lifting capacity: Up to 16 ton

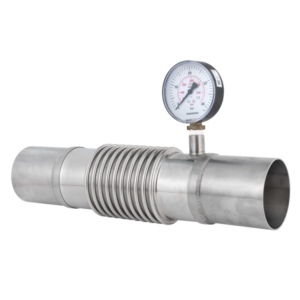

TEST&CERTIFICATION

• Expansion Joints are the parts of piping system of pressurized equipment in this respect construction of the expansion joints are designed and produced according to PED 2014/68/EU&ASME U Stamp-U2 Stamp.

• Expansion joints are exposed to hydrostatic pressure at 1,5 times of design pressure.

• For full vacuum applications, vacuum test at 760 Hg/mm is also applicable.

• Additionally, gas leakage detection with helium is advised for proper tightness.

AYVAZ SPECIAL EXPANSION JOINTS

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.