Surface and Bottom Blowdown Valves

If water inside boiler is not finished very well in spite of its preparation phase, density of insoluble materials (TDS) will be increased because of steam producing. It will cause harm to boiler and pipeline if determined limits is passed. These harms cause errors to equipment. Insoluble materials are dragged with steam and they can increase the conductibility of condensate and cause energy loss. The insoluble material-generally calcium and magnesium salts- consists during the steam producing and it is removed by some techniques for optimum TDS level. This operation is called BLOWDOWN.

There are 2 types of Blowdown.

1. Top Blowdown

2. Bottom Blowdown

Top Blowdown: If insoluble materials are in liquid phase, in other terms they do not sink and melted in the water; they are automatically removed from system by YBS-10 Top Blowdown System.

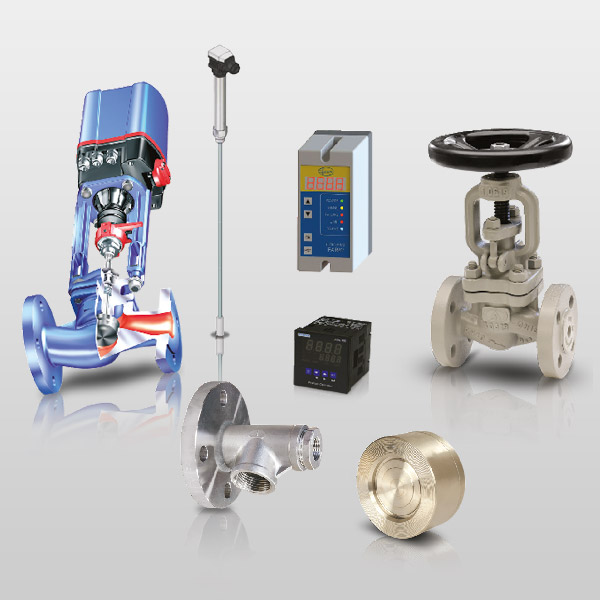

YBS-10 is composed by 1 piece of conductibility detector, 1 piece of transmitter, 1 piece of control valve, 1 piece of PID conductor and control panel. It can be possible to add 1 piece of plated heat exchanger and 1 piece of cycling pump, if it requested for energy recycling system.

Bottom Blowdown: If insoluble materials are in solid phase, in other terms they sink; they are removed from system by DBV-10 Bottom Blowdown Valve.

DBV-10 is composed by 1 piece of timer, 1 piece of completely stainless steel 3 pieced ball valve with actuator, 1 piece of pneumatic actuator and 1 piece of solenoid valve.

Advantages of Blowdown System:

1. Increments boiler safety and efficiency

2. Savings labor power

3. Suitable for every kind of steam vessels

Energy Recycling by YBS-10:

According to determined TDS level, if necessary equipment is added to the system, saturated water which is removed by blowdown valve, can be used for heating of vessel feeding water by helps of plated heat exchanger.

YBS-10 Top Blowdown System:

It automatically helps to control the level of melted TDS. There will be energy save by automatic blowdown operation. Energy recycling system can be installed if it is requested to get more savings. There can be 5-10% energy save at fuel consumption. For arranging of TDS amounts please contact with producer of vessel.

DBV-10 Bottom Blowdown Valve:

It removes blowdown automatically according to arranged time line.

Working Pressure:

Up to 16 Bars

Working Temperature:

Up to 150 ºC

Application Area:

Steam vessels

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.