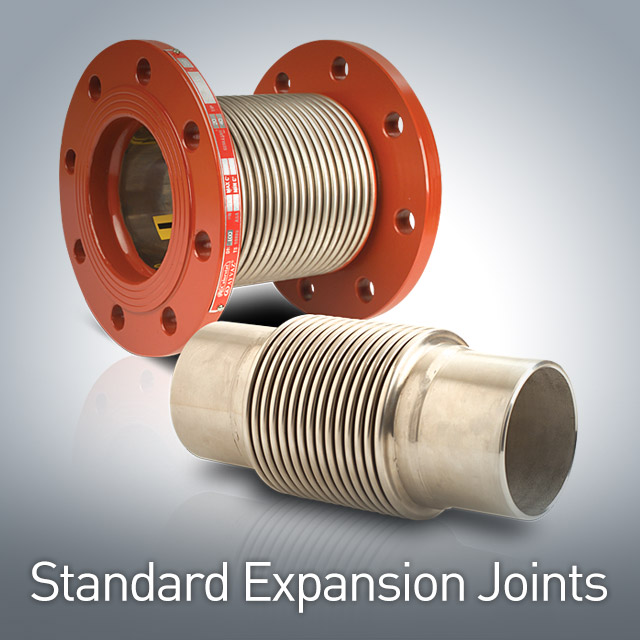

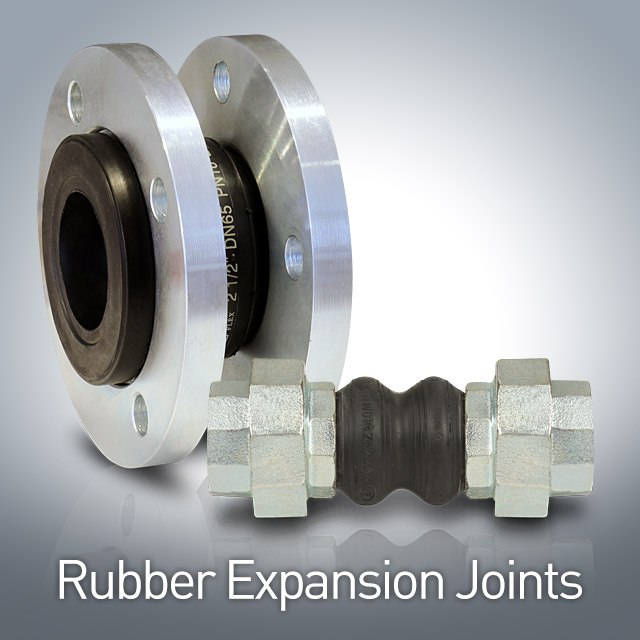

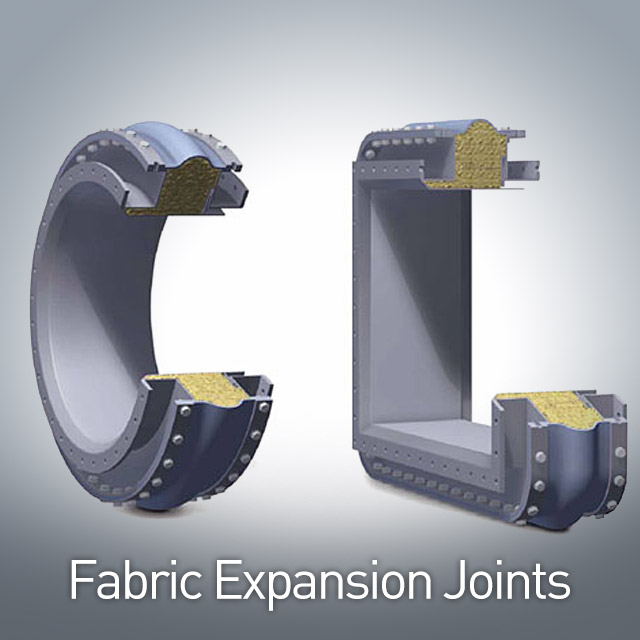

WHAT IS EXPANSION JOINT?

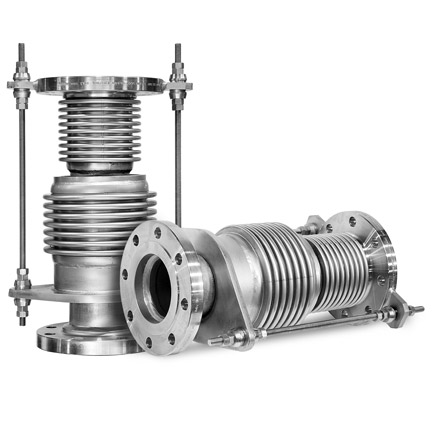

Expansion Joint is a product that maintains the piping system and protects equipment by absorbing high stress magnitude on pipes due to outer temperatures that may influence energy delivering pipes, pipe expansion or contraction caused by temperature changes in fluids, equipment vibration problems or seismic motions.

Ayvaz designs and manufactures bellows expansion joints from the simplest standard expansion joints to highly complex expansion joints which are designed especially on the basis of individual customer requirements. Metal expansion joints are single or multi-layered stainless steel expansion joints with a high level of expansion absorption and a low spring rate.

TAKE A CLOSER LOOK

We have been offering various types of expansion joints for decades.

50

YEARS OF EXPERIENCE

5

FACTORY

10000+

ANNUAL PRODUCTION OF EXPANSION JOINTS

110+

COUNTRIES TO EXPORT

ENGINEERING

Ayvaz, metal bellows are designed according to EJMA coding (10th edition) EJMA rules apply to single or multiple layer bellows expansion joints, unreinforced, reinforced or toroidal, subject to internal or external pressure and cyclic displacement.

The bellows shall consist of single or multiple identically formed convolutions. The suitability of an expansion joint for the specified design pressure, temperature, and axial displacement shall be determined by the methods described in EJMA. Construction of metal expansion joints is completed according to EN14917:2012 European standard and in compliance with PED 2014/68/EU requirements.

Apart from European standards, Ayvaz also deals with the design and production of metal expansion joints according to ASME standards, Section VIII div 1& div 2 (U stamp, U2 stamp).

- DN15-DN 7000

- Up to 150 barg design pressure

- Materials: All stainless steels & high alloyed stainless steels including Duplex, Incoloy, Inconel, Hastelloy, Titanium, Tantal-coating etc.

- Design codes: All, including EN 14917, EJMA, AD 2000, EN 13445, ASME Sec.VIII Div I&II

QUALITY OF OUR EXPANSION JOINTS

We aim to provide products to work with maximum service life for any operating condition. As the leader of expansion joints production, Ayvaz operates its production complying with the standards that recognized by the most important national and international bodies and industrial associations.

SECTORS

REFERENCES

We have our signature on giant projects.

Ayvaz brings reliable solutions for decades, expanding its area of activity with new products and new investments. From giant petrochemical plants to hydroelectric power plants, Ayvaz's solutions are taking place in various sectors and industries worldwide.

Ayvaz is a member of Association Euro-Qualiflex (AEQ) which is the association of the leading European manufacturers of flexible metal hoses, bellows and expansion joints. We export our high-quality products to 100 countries and we've provided solutions for hundreds of thousands projects so far.

SECTORS

ENGINEERING SERVICES

We are used working with complex specifications and advanced technical solutions and as part of our service we provide: CAD, 3D parametric design and pipe stress analysis.

ON-SITE SERVICES

Installation of expansion joints is complex and calls for experienced installers. Therefore customers often require our assistance and advice. In addition to design and manufacture pressure balanced expansion joints in general, we have an experienced service team that assists customers on all kinds of onsite work including:

- Full installation

- Supervision of installation

- Repair/refurbishment

EMERGENCY FAST TRACK SERVICE

If your production is at risk of stopping, if there is an urgent intervention in your system, you cannot waste time with standard production and delivery processes. Ayvaz offers you a special service called "Fast Track Service". In this way, you get the product you need in the fastest way, without waiting in line, wherever you are in the world.

Case Study: Onsite Repairing The Vaporizer Bellows

Inquiry Form

Please send us your inquiry using our contact form and we will contact you immediately.